Molding Department

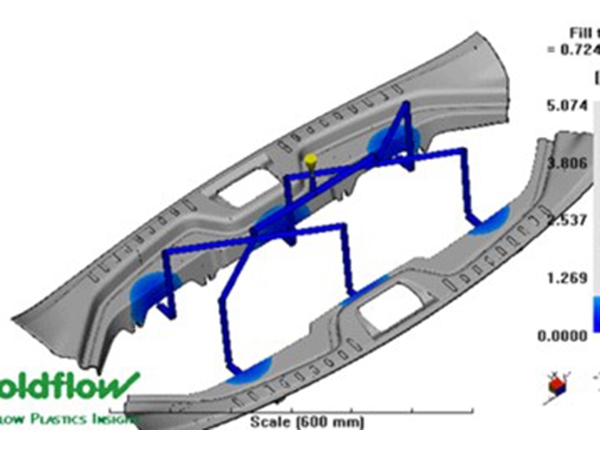

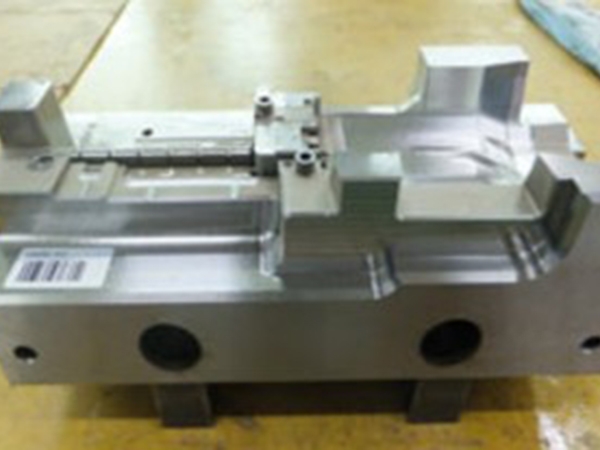

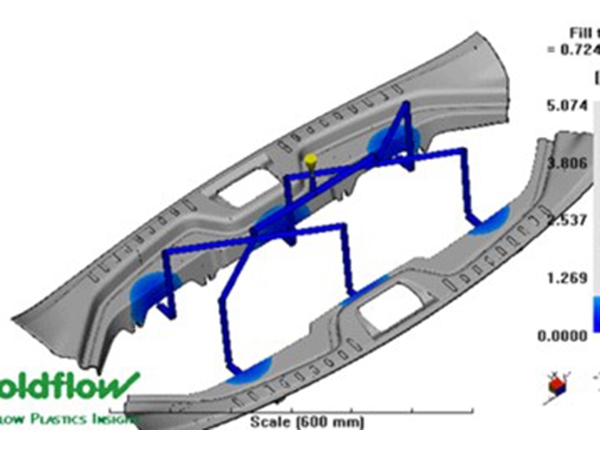

We understand that injection molds are often used in high-volume applications where it needs high dimensional accuracy cavity-to-cavity, thus will require precise, detailed designs and machining to achieve this. At Akino, we use state-of-the-art 3D design softwares, like UG, Pro-E, Solidworks, AutoCAD and etc, no matter what you have at hand, even if it’s just a concept, we will help you transforming it into reality. We pride ourselves in helping our customer by becoming involved early in the process of product design to help prevent end use product failures.